I. hydroforming press mechanical use:

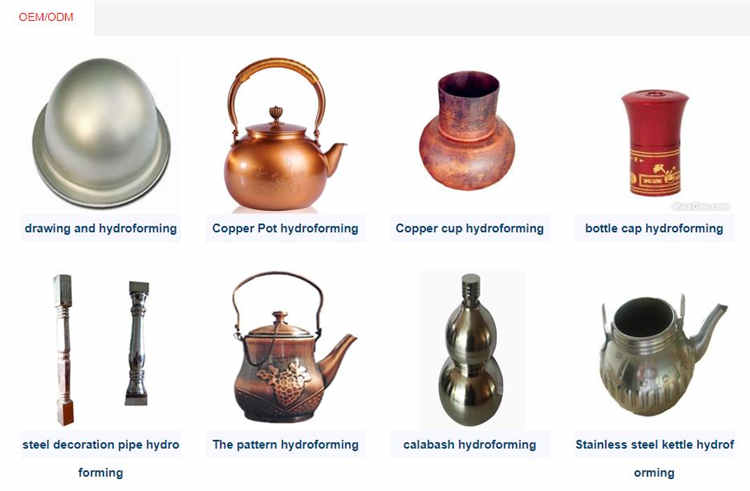

It is mainly used for lamp shade, copper handicraft, cup, pot, decorative craft column and so on.Specially designed for the production of stainless steel special-shaped pot, special four-column rapid expansion extruding expansion machine for the realization of this advanced technology and the development and manufacture of special expansion mechanical equipment.It is especially suitable for the forming process of stainless steel, copper, aluminum pipe fittings, cups, POTS and so on.

This hydroforming is mainly applicable to plastic material forming parts with complex surface and high linear flow, specially designed and manufactured for the production of stainless steel special-shaped pot and special-four-column rapid extrusion bulging machine to realize this advanced technology.Water expansion hydraulic press: lampshade, copper crafts, cup, pot manufacturing, stainless steel decorative technology column, complex pipe manufacturing and other industries.

The hydroforming press manufacturing processing products

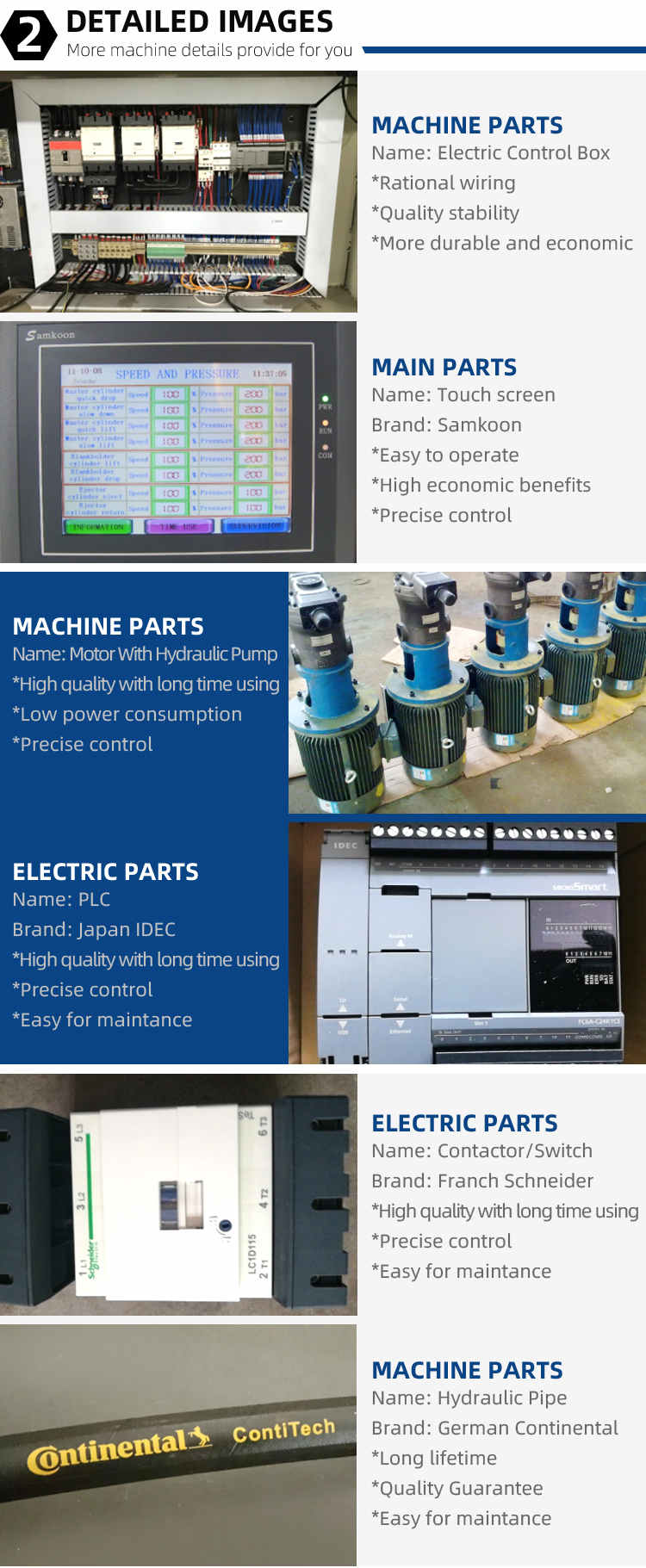

Features: Multi-speed control for Ram-drawing fast-down, slow-press, fast-back in high efficiency. Automatic calculation function in semi-auto operation. The main seals are popular ones and imported for long working life. The key electrical and hydraulic components are adapted well-known brands to ensure presses in good performance and more reliable. The 4 posts and piston shafts had been heat-treated and chrome coated in surface. The infra-red curtains are all our standard safe equipment in presses. The centralized lubricant system can prolong the life of the machine. High working pressure can form the products with clear shape edge. The worktable can be movable to load/unload products easily in order to save the height of whole press and make it more stable and reliable. The hydraulic system fitted with two-way cartridge valve to reduce the pressure loss.

PERFECT PRODUCTION LINE

Manufacturer of hydraulic press equipment integrating professional design, research and development, manufacturing and service.

Cooperation customer case

Actually Water Bulging Machine belongs to a kind of metal tube hydroforming equipment, its principle is to use mechanical energy to make the hydraulic system pressure cylinder produce kinetic energy expansion pipe, the medium of emulsification water to produce ultrahigh pressure under the water up mould clamping, through recommended on both sides of the master cylinder clamping cylinder of hydraulic press forward extrusion in the mould of the tube to produce metal flow to fill material feeding plastic deformation, the device also belong to the horizontal water machine, actually master cylinder hydraulic vertical structure, the beam slab hydrating and upper and lower clamping process is called a simple expansion products such as cups this applies to a bigger pot of hardware products, this technology is not for filling material feeding.And then the horizontal structure is relatively more expensive than the vertical structure.

But it is not absolute, high pressure water up in the machine industry has a application industry can do inventory that is installed tube conformity of stainless steel pipe industry, the industry of water equipment tonnage is generally more than 200 tons, 300 tons, 350 tons, 400 tons, 500 tons more, water processing of stainless steel material in 0.1 2.0 mm thick, processing of pipe length in 30 mm - 1000 mm, processing pipe diameter in DN15-12, this standard belongs to the national standard of the conformity of fitting, the water rose mold can also be made standard,However, the accuracy of the clamp ring at both ends of the control clamp pipe is high.There are two modes in China: one is to buy equipment to buy molds, pipe fitting company production, and supporting the production lines of pipe cutting machine, pipe bending machine, deburring machine, etc., the second is the pipe fitting OEM.A second domestic model is slowly emerging.Before the forming of stainless steel compression is rubber expansion, lead expansion, oil expansion, there is a mechanical stress expansion.But with the national control of environmental protection, the rise of water swelling and pressure tube technology has replaced the traditional process, this process green, environmental protection, expanding medium emulsified water can be recycled pollution-free.