Hydroforming machine (also known as: water expanding machine) belongs to a hydraulic machine type, is a new replacement of the traditional ordinary rubber expanding hydraulic machine.It is a use of emulsified water as a liquid transmission medium, through the hydraulic machine mechanical energy into the kinetic energy of water to process stainless steel, aluminum, copper, iron and other materials of the product of the machine.

Hydroforming processing products:

Copper tube hydroforming machine:

Material: suitable for material copper, bronze, brass material such as wall thickness of the product in the high pressure water molding

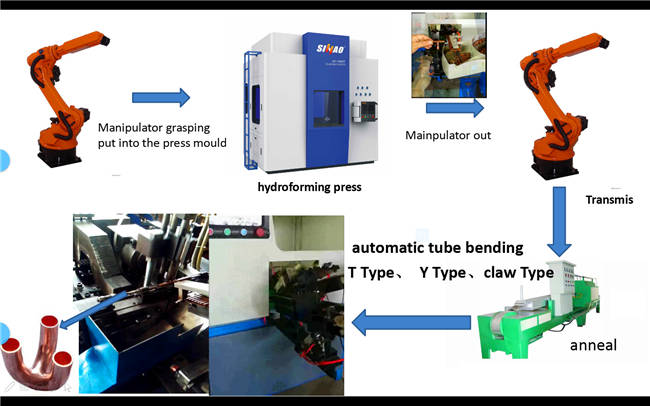

The brass product size specifications: T tube, Y type pipe, L For direct copper tube, 135 ° 45 ° bend, copper pipe, copper 90 ° bend tube high pressure liquid bulge forming in high pressure water.

Applicable copper tube expansion diameter: 8 mm - 2000 - mm (according to other users)

copper tube internal high pressure forming machine:ube wall thickness: 0.5 mm to 0.5 mm (according to other users) Pipe length: 50-3000 - mm.

Mould:

Tee tubes Hydroforming mould need of 30 days to be made .The workshop have the inventory machine to vitro professional training test and debugging services .

Ton type:150t、200t、300t、380t、500t、740t、1100t 、2000t

Advantages of internal high pressure molding technology:

1> product technology before: blanking -- stretching -- (multiple) spinning -- (multiple) swelling.Tedious and costly 1, spinning production: batch is small, forming size is not stable, can not arbitrary forming of high pressure shaped surface products. 2. Production situation of rubber expansion: a, if there is no rubber expansion of 100 products, a rubber will be replaced, increasing the cost;Increased costs.B. The product size of each expansion is unstable, with large precision error and many defective products. > water swelling new process: blanking - stretching - water swelling forming. The new > process USES water expansion instead of spinning to reduce cost and provide efficiency.

Study and application of high hydroforming technology in thin-wall variable diameter copper tube

Other provide:

1 SHS TEE (three) flaring Shaping Machine TEE (three ends) pipe Expanding and Shaping Machine (5 t - 30 t) ; 2 SHW 90 ° 45 ° Angle (Angle Right) here (Elbow) Expanding Machine belling Machine (5 t - 30 t) ; 3 SHZ pass-through (double Two ends) of draw mouth Machine Tube Tnds Trimming Machine (50 t to 100 t) ; Expanding machine usage instructions ; Applications: for pipe Tube range: 30 5 mm - 30 100 mm Copper Tube, aluminum Tube, iron pipe Copper/brass/Aluminium/Steel Tube For the Length range: 50 mm - 1000 mm ; Wall Thickness: 0.5 mm to 5.0 mm ; Production Capacity: 2-3 seconds/root 2-3 Sec/PCS ; Driving mode Driven: Hydraulic Hydraulic;

The copper hydroforming machine leading technology with tap water to squeeze straight pipe into three, reduce the injection of lead, drilling and other technology, save cost and production time, in order to ensure the stability of water pressure, we use a pressure equalizer to stabilize the pressure in the copper pipe squeeze three, so that the copper pipe in the extrusion process to maintain a constant pressure;The two sides of the cylinder to adjust the synchronization performance, we also used the synchronizer to synchronize the two sides of the cylinder, so as to achieve a higher yield (can process the diameter of more than 7 mm of copper tube, pass rate of more than 98%, molding cycle of about 10 seconds/time).