Hydraulic press technology widely used for bending, flanging, stretching, forming and cold extrusion processes such as stamping, press is a kind of static pressure to processed products.

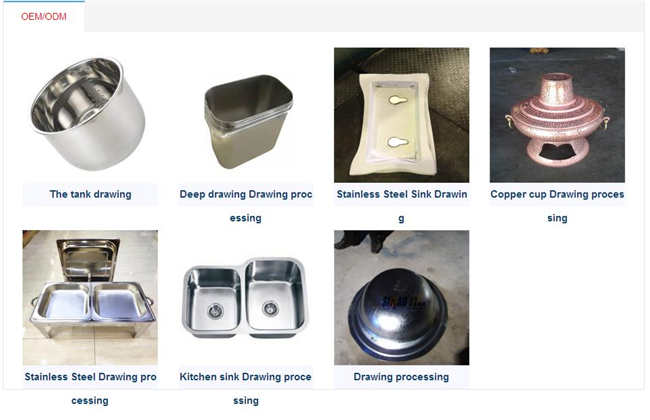

The hydraulic press second reference drawing machine molding products: metal shell, garden tools, air conditioners shell, water heater, gas burner, shell, heater shell, barbecue outdoor products, stainless steel sink, stainless steel tableware, stainless steel kitchen utensils, stainless steel hotel ware, electric rice cooker stainless steel tank, aluminum tank, auto parts, engine parts, motorcycle parts, metal stamping parts, metal furniture stretching, heaters, stretching, lamps shell extension, daily industrial products and so on.

such as The Second process of the metal hydroforming processing

The hydraulic press second reference drawing machine molding products: metal shell, garden tools, air conditioners shell, water heater, gas burner, shell, heater shell, barbecue outdoor products, stainless steel sink, stainless steel tableware, stainless steel kitchen utensils, stainless steel hotel ware, electric rice cooker stainless steel tank, aluminum tank, auto parts, engine parts, motorcycle parts, metal stamping parts, metal furniture stretching, heaters, stretching, lamps shell extension, daily industrial products.

Four-column drawing oil press is used for tableware, kitchenware, motor shell, household appliances and lighting parts and other parts of metal or non-metal forming, embossing, stretching and cutting edge The lower top cylinder oil press is suitable for almost all pressure processing processes.At present, hydraulic press is mainly applied in the following fields: 1, non-metallic materials, such as SMC molding, automotive interior molding, rubber products, etc.;Hot pressing of wood products, such as plant fiber plate, profile hot pressing processing; 2, such as pressing, correction, plastic sealing, embossing and other processes. 3. Stamping and drawing of metal sheet parts, mainly used in the forming of metal covering parts in automobile and home appliance industries;Pressure forming of metal parts, mainly including die forming, extrusion forming of metal profiles, cold and hot die forging, free forging and other processing technology; 4. Powder products industry, such as magnetic materials, powder metallurgy, etc.; 5, mainly is suitable for the shaft parts, profile correction and shaft sleeve of pressed parts, sheet metal parts of the bending, stamping, shape, the simple components of the tensile plastic products, machine tools, internal combustion engines, textile machinery, shaft, bearing, washing machine, automobile motor, air conditioner motor assembly line, electric appliance, military industrial enterprises and joint ventures and other industries use.

More efficient hydraulic molding technology recommended :Hydroforming technology for sheet metal