Abstract: Aiming at the faults of traditional technology in faucet manufacturing process such as low produc- tion efficiency, high cost, heavy pollution, large power consumption and uneven dimensions, the internal high-pressure hydroforming technology has been adopted in the text to produce such kind of products. The process analysis and design of tool have been carried out to the mass production. It is proved that the sim- ilar product with complex shapes can be obtained by three times of internal high pressure hydroforming process, which substantially improves the utilization of materials and production efficiency.

Key words: Faucet; Internal High Pressure; Hydroforming; Technical Analysis; Practical proof

With the continuous improvement of people's living standards, consumers are attracted to the dragon The demand of the head is more and more artistic, high-grade development direction, its outside The shape structure and forming process become more and more complicated, and the traditional forming process The faucet has been unable to meet the market demand.A tradition of faucets Shape process has lead bulging forming (lead is harmful to human body), plastic bulging forming (medium Quality glue waste serious), oil swelling forming (serious pollution), welding forming (size instability) and casting (trachoma, porosity), etc.And the water The high pressure hydroforming forming process has the following characteristics: green environmental protection(medium water environmental protection, clean, zero pollution), energy saving and consumption reduction (servo system Energy saving 30%~70%, material utilization rate above 80%), capacity Improve (size stable, mass production, efficiency increased by 10-50 times), Safe and reliable, widely used.Aiming at the traditional faucet forming process In this paper, a new forming technology of hydroforming pressure hydroforming is proposed Methods.

1、the analysis of hydroforming process of faucet

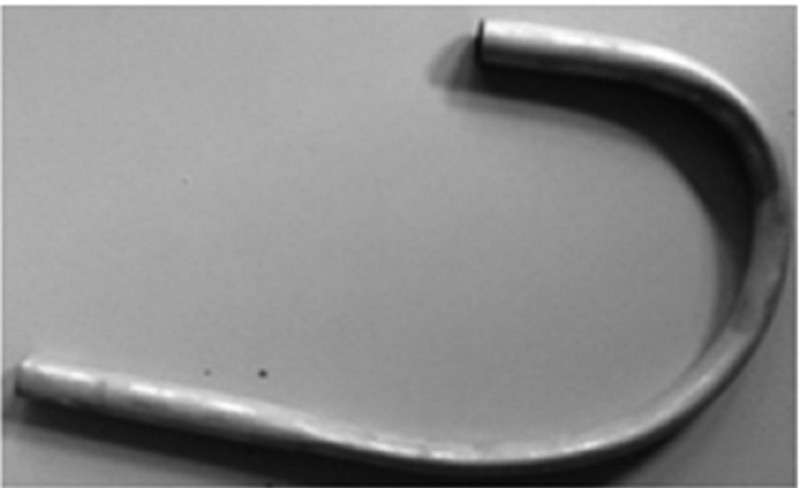

Figure 1 shows the final product diagram.First of all, the process route is defined as: pipe cutting - pipe bending - flattening - hydroforming 1- annealing 1- hydroforming 2- Annealing 2- hydroforming 3- cutting - polishing - chrome plating.This paper only analyzes the bending pressure and hydroforming forming process of faucets as follows.

The product is required to use stainless steel SUS304, with the minimum wall thickness not less than 0.8mm.And by measurement, the hose The circumference of the smallest outside diameter of the head is 83.26mm (diameter is about 26.5). The diameter of the inlet of the faucet is 52, which is the maximum diameter of the faucet. The diameter of the outlet of the faucet is 38.According to the principle of keeping the sectional area of expansion constant, the stainless steel fittings with external diameter of ka26 and wall thickness of 1.6mm are selected for expansion processing.Because the stainless steel pipe in the process of water bulging forming, water pressure will produce expansion and stretching effect on its material, so in the process of water bulging forming, it needs to be supplemented by external forces, in order to effectively prevent the wall thickness of the bulging become thinner.In addition, because the diameter of the inlet end and the outlet end are different from each other, the inlet end needs to adopt the feeding and sealing process, while the outlet end does not need the feeding process, only the sealing process needs to be considered.

2、bend

The cavity of the mould is fixed and not bent when water expands Therefore, the shape of the bend must be with the first expansion of the mold cavity The shape is basically the same, and the bending length and radian of the stainless steel fittings are both You need to be well positioned to ensure that each product is essentially the same.

(3) squish. Since the middle section of the product is flat, an additional process should be added, namely, flattening the middle part of the bent pipe and shaping the whole bending pipe at the same time, so as to ensure that the shape and size of the whole bending pipe are the same, so as to facilitate the next production process (i.e. the first hydroforming) to proceed smoothly, as shown in figure 3.

(4) the first hydroformed.

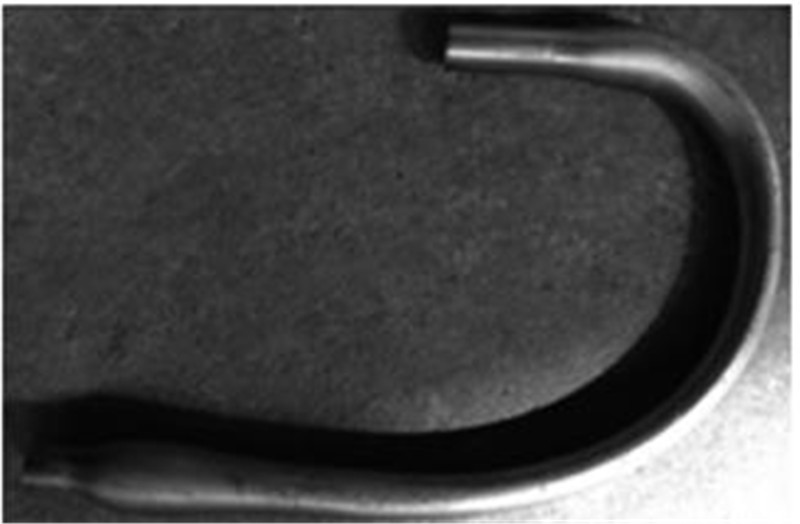

After analysis and calculation, the faucet technology The difficulty is from the diameter of the raw material to the diameter of the inlet end, At the same time, cutting and material flow problems are considered, the inlet end is at its maximum straight The diameter should expand to Katherine 53;Similarly, the maximum diameter of the outlet end should be water expansion Go to computer 42.According to ordinary stainless steel SUS304 material The theoretical value of elongation of 40% is calculated, but the actual value is only 25%~ 30% elongation, so after three times of hydroforming to reach the product requirements of the ruler Inches.The maximum part of the first hydroforming mold design is computer 32.5, press The expansion ratio is about 1.25 to the expansion, and both sealed water and feed 5mm.Out of the The maximum part of the first expansion mold is the computer 29, according to the expansion ratio About 1.12 to bulge, and only sealed water does not feed.Stainless steel SUS304 tube hydroforming pressure up to 120MPa, the outer wall all stick to the cavity, bulging The wall thickness at the maximum position is 1.28~1.33mm, and the product surface is not raised Wrinkle, hydroforming effect is very good.Stainless steel SUS304 material after hydroforming The stress and elongation have reached the edge of the limit, so they have to pass through The second hydroforming can only be carried out after high temperature solution heat treatment, as shown in figure 4.

(5) the second hydroformed.

The most important part of the second hydroforming mold design is computer 41.5, which is about 1.28 according to the expansion ratio, and it seals the water and feeds 5mm.The maximum part of the second water expansion mold design at the outlet end is 35, which is about 1.2 according to the expansion ratio, and only water is sealed without feeding.SUS304 tube water swelling pressure up to 160MPa, all the outer wall is pasted to the cavity, the maximum position of swelling wall thickness is 1.0~1.1mm, there is no wrinkle on the surface of the product, water swelling effect is very good, after water swelling solution annealing treatment, See figure 5.

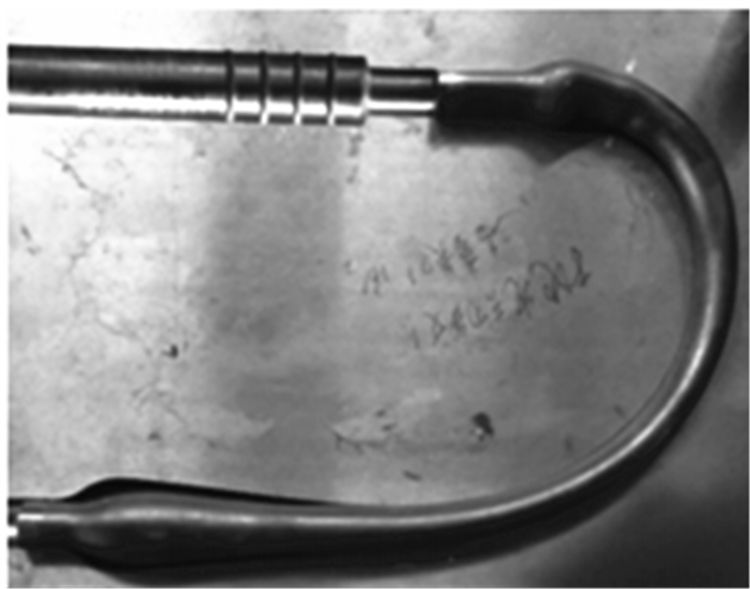

The third swell.

The most important part of the third expansion mold design is the computer 53, which is about 1.28 according to the expansion ratio and seals the water Feeding 5 mm.The most important part of the third expansion mold design for the outlet end is the computer 42, which expands according to the expansion ratio of about 1.2, and only seals the water without feeding.In consideration of the edge problem at the compressed part, the water expansion pressure in the SUS304 tube can reach 250MPa, the outer wall is all pasted to the cavity, and the maximum wall thickness at the bulging part is 0.8~0.85mm. There is no wrinkle on the surface of the product, and the three-dimensional sense of edge at the compressed part is more obvious, and the water expansion effect is very good.After cutting off the excess process materials at both ends of the inlet and outlet water, they reach the product design size, as shown in figure 6.

The engineering practice

After calculation, with P water =250MPa of ultra-high pressure water expansion pressure, then Clamping force of main cylinder F1=P water A1=250×19400× 10-3 =4850kN, F1=5000kN.A1 is the projection surface when the faucet is placed horizontally Product, measured by software A1=19400mm2 ;Calculate the clamping force of the side cylinder F2=P water A2=250×0.785×262× 10-3 =132kN Sealing process, F2=400kN.This process is produced by ourselves Development and production of multi - station high - pressure water expansion forming machine HF98/3-820t production, and achieved good results.This product After water expansion compared to the previous casting product optimization: weight reduction 30%, saving costs from raw materials;The outer surface is flat, facing the post The polishing treatment of the surface is more convenient;The internal high pressure water expansion machine is easy to operate, works by 8 hours, yields 2000~2500 pieces per day, high efficiency, convenient Mass production.

To sum up, this kind of hollow complex parts can be formed by internal high pressure water expansion forming technology instead of some traditional processes, and it has light weight Chemical, cost saving, stable quality, improve efficiency, green environmental protection and other significant advantages.At present, the technology of internal high pressure bulging has been widely used in military industry, such as aerospace tongji waveguide square copper tube;Auto parts industry, such as exhaust pipe, water tank, bumper, auxiliary frame, rotor sleeve, buffer, etc.Sanitary ware industry, such as faucet;Civil stainless steel pipe industry, such as straight, tee, elbow clamp pipe;Civil refrigeration and heating copper pipe industry, such as straight, T, Y, L copper pipe;Civil hardware industry, such as rice cookers axe - type pot, vacuum cup, vacuum cup, decorative technology column.In our country, many hollow parts also adopt the traditional welding or casting process, This market needs to be developed and expanded.