Hydroforming mould Abstract: when the super-high pressure liquid is applied to the tube, the tube blank is fed with the axial thrust at both ends of the tube. Under the joint action of the two external forces, the tube blank has plastic deformation, and the hollow parts whose shape and precision meet the technical requirements are obtained.It is one of the key technologies to realize the lightweight of automobile structure for the special pipe fitting of exhaust system and hollow frame of chassis, such as the auxiliary frame.

The auto hydroforming mould:

The design of internal high pressure moulding mould needs rich production practice experience, the mould design of new products, new technology is impossible to succeed, more or less there will be some unreasonable structure or other defects, the product can not be formed smoothly.In order to solve these problems, this paper simulates the process of tube autoforming with the finite element simulation software MSC.Marc, verifies the rationality of the mould structure, finds the existing defects and re-optimizes the mould.This can make up for the shortage of experience design, shorten the mould design and manufacturing cycle, improve the work efficiency, avoid the unreasonable design caused by the waste of resources, similar mould design has a certain reference.

The design of internal high pressure moulding mould needs rich production practice experience, the mould design of new products, new technology is impossible to succeed, more or less there will be some unreasonable structure or other defects, the product can not be formed smoothly.In order to solve these problems, this paper simulates the process of tube autoforming with the finite element simulation software MSC.Marc, verifies the rationality of the mould structure, finds the existing defects and re-optimizes the mould.This can make up for the shortage of experience design, shorten the mould design and manufacturing cycle, improve the work efficiency, avoid the unreasonable design caused by the waste of resources, similar mould design has a certain reference.

The Stainless steel tee pipe fitting hydroforming mould:

Technical realization elements: The purpose of the invention is to provide a left-right symmetrical three-way pipe internal high-pressure forming equipment, in particular a pipe internal high-pressure forming equipment that USES the hydraulic follow-up sealing of the left-right feed pushing head.

What is the principle of tube hydroforming: after the upper and lower dies are combined, the tube is sealed by the left and right thruster and pressure forming medium is injected into the tube. Under the combined action of the axial feed of the left and right thruster and the internal pressure, the tube high-pressure forming is realized.Compared with the traditional processing technology, the parts obtained by this forming method have a series of advantages, such as low cost, light weight, material saving, less processing, high forming quality, good mechanical properties and high stiffness strength.

The bellow metal corrugated control preparation process

The invention discloses a ripple control technology, with the following steps: to a certain size of the pipe into a wall, make the wall a stagger need position in formation of corrugated pipe, placed with a wall of tubing to a mold cavity, cavity within weeks of surface has concave and convex corrugated structure, the pipe port of filling the high pressure fluid, using the high pressure fluid pressure and makes the pipes located in parts of the mold cavity dilation.Under the limitation of the ripple structure on the inner surface of the die, the initial ripple with wave peak and trough is formed on the pipe.The roller is used to roll on the trough of the initial ripple along the trend of the initial ripple to make the height difference between the peak and trough of the initial ripple become larger.

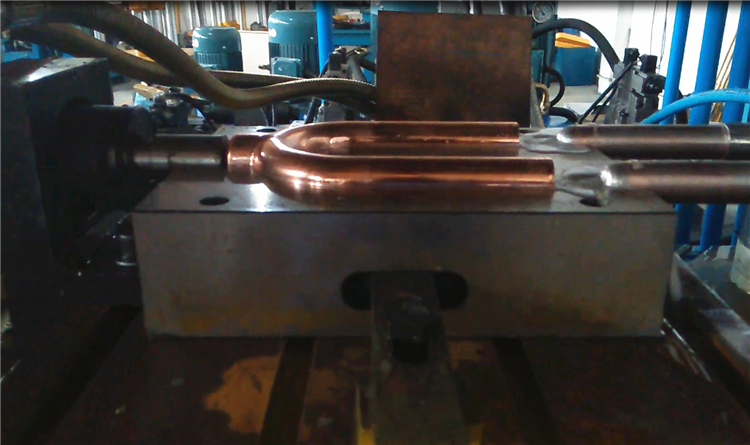

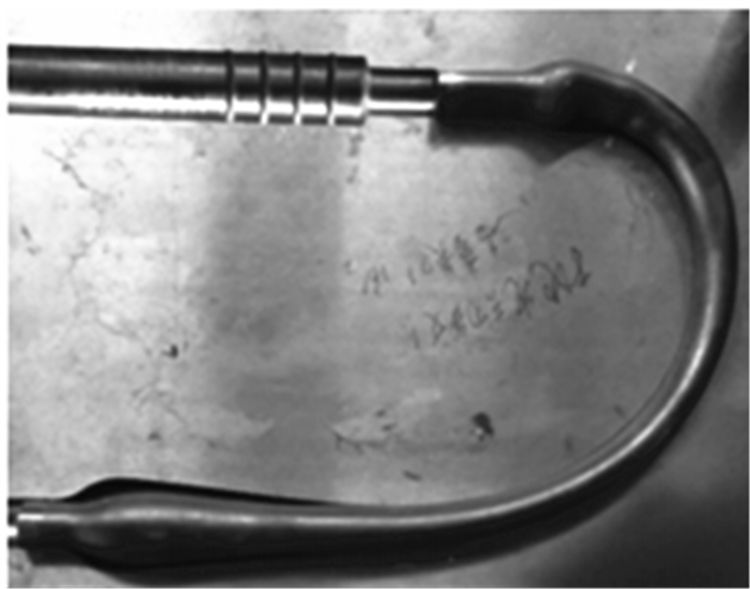

The Y type copper tube hydroforming mould:

For the y-type tee tube, due to the asymmetry of its structure, the axial feeding ratio of left and right punch in the process of hydroforming has a great influence on the forming.Through experiment and numerical simulation, the effect of the ratio of feeding material on the wall thickness of y-shaped tee tube and the defects in the forming process were studied.The results show that the wall thickness of the rounded corner of the left transition zone is the largest, followed by the rounded corner of the right transition zone, and the wall thickness of the top of the branch tube is the thinnest.Increasing the feeding ratio can improve the thinning of the wall thickness of the branch and tube to a certain extent, but excessively increasing the feeding ratio of the left and right sides will cause the concave defect in the left rounded corner of the specimen.

Using the numerical simulation of Y type tee tube high pressure forming process was studied, studied 87 mpa to 145 mpa range of five different internal pressure loading path forming process, analyzes the concave transition zone, the causes of defects such as lack of height of branch pipe and the inner pressure of 116 mpa when parts forming process of a typical location of the wall thickness change, and the influence of internal pressure on the part wall thickness distribution.The numerical simulation results show that 106MPa ~ 126MPa is the appropriate pressure range for forming y-type tee pipe, but the minimum wall thickness of parts formed by internal compression is different.

The process analysis and manufacturing practice of internal high pressure hydroforming technology in faucet production

Abstract: Aiming at the faults of traditional technology in faucet manufacturing process such as low produc- tion efficiency, high cost, heavy pollution, large power consumption and uneven dimensions, the internal high-pressure hydroforming technology has been adopted in the text to produce such kind of products. The process analysis and design of tool have been carried out to the mass production. It is proved that the sim- ilar product with complex shapes can be obtained by three times of internal high pressure hydroforming process, which substantially improves the utilization of materials and production efficiency. Key words: Faucet; Internal High Pressure; Hydroforming; Technical Analysis; Practical proof