The Company have own instrument hydroforming processing center, manufacturing workshop, can carry on OEM order and ODM order for overseas clients. according to customer requirements to develop new products.

At present, the key equipment of the project is independently researched, developed and designed in China, and the supporting equipment also includes pipe bender, pipe cutting machine and pipe making machine. The company plans to gradually improve the offline simulation, high-frequency welded pipe development and mold localization manufacturing capacity.Strive to become the largest internal pressure molding tube research and development base.

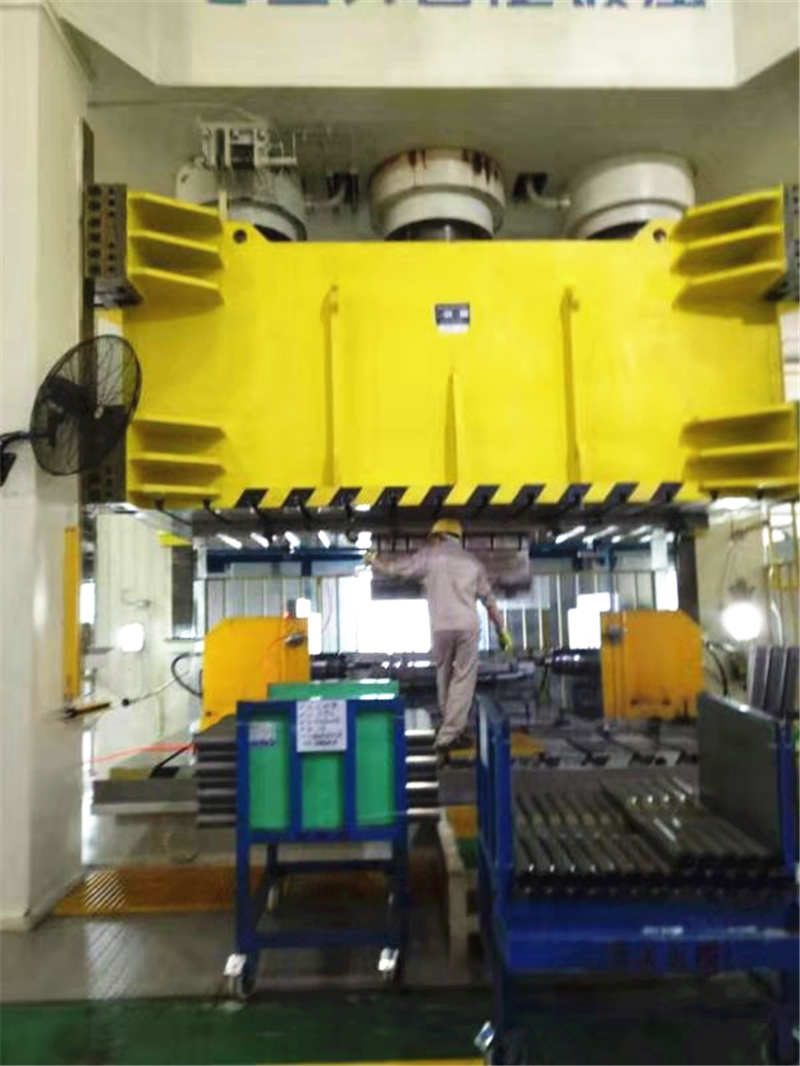

The hydroforming equipment represents the highest level of our zirconium manufacturing industry, hydraulic machine tonnage, table, control and process are unique in China, It fill the domestic production and manufacturing of large internal high pressure pipe fittings forming inferior position.The equipment adopts the slider horizontal tracking and rectifying system, and adopts the closed-loop system in the pressure and position control of the pipe fitting forming, which strictly guarantees the geometric accuracy of the special-shaped pipe fitting pressing.The equipment adopts the system integration optimization design, can according to the user's workpiece process requirements for the mold, the mainframe, the system coupling design, is the parameters and comprehensive performance to achieve the best.This equipment is at the international leading level in the complete set of equipment for pressing large-scale pipe fittings.

The processing application scope of the hydroforming machine: Internal high-pressure forming body parts: A column, B column, forming instrument panel beam, forming seat frame, C column, space frame, forming roof rail, forming beam, forming windshield bracket, etc. Internal high-pressure forming engine parts: camshaft, crankshaft, catalytic converter, exhaust manifold; Internal high-pressure forming chassis parts: bumper, beam, joystick, control arm, radiator housing, rear axle housing, steering string, frame rail, joint, auxiliary frame, engine bracket, trapezoidal frame, etc.

This paper introduces the latest progress in the equipment of tube internal high-pressure forming, key technology of process mold and industrial application.Batch production, high pressure forming mold, has solved the key technical problems, such as porous synchronous hydraulic punching mold, developed a large complex hydraulic punching mold, reveals that the stress and deformation of the mold and its relations law of dimensional precision, extending the numerical simulation technology in the development of internal high pressure forming mold. In industrial applications, set up multiple internal high pressure forming industrialization demonstration base, was developed for the domestic auto makers and parts factory production with large internal high pressure forming machine, and it has been successfully applied in the SUV car beam, car auxiliary frame and exhaust system of auto parts, such as mass production.