The principle, characteristics and application of hydroforming technology for tube parts are summarized, and the basic form, structure and principle of forming equipment are emphatically introduced

With the development of lightweight structure, in recent years, the application of tube autoforming is more and more extensive, especially in the automotive industry.This paper introduces the typical structural parts made by internal high pressure forming, such as branch pipe parts, special-shaped pipe parts and hollow shaft parts.The development trend of internal high-pressure forming was discussed.

In this paper, the tube Internal high pressure forming (Internal high pressure forming) technology were studied, to study the plastic transition fillet process design, Internal high pressure forming process curve of load, the Internal high pressure forming area length and the limit expansion ratio, the results showed that found that reasonable Internal high pressure forming technology have important effects on the formability, and determine the forming quality of tube;Through the experiment of internal high pressure forming, it is proved that the wall thickness reduction rate of steel tube should be controlled in the process of pipe bending.The application of internal high-pressure forming technology can effectively promote the rapid development of automotive lightweight technology.

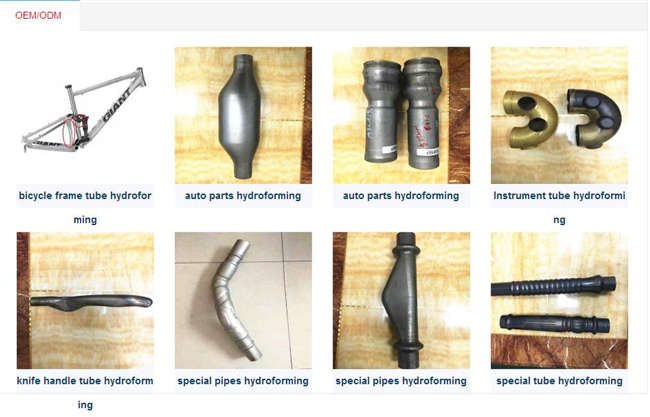

The Processes and Advantages of Internal High Pressure Forming

As one of the important application fields of automobile structure lightweight, tube hydroforming technology has developed rapidly in recent years. Many foreign automobile companies have applied it to the production of hollow lightweight parts. The process characteristics and application of internal high pressure technology are introduced. The basic structure and key technology of internal high pressure forming equipment are described.